Building and programming a USB auxiliary display using a SparkFun Pro Micro, an HD44780 LCD module, and an PCF8547 I2C-to-parallel IC

This article is about how to use the ubiquitous HD44780 LCD module

with a Arduino-like microcontroller board such as the SparkFun

Pro Micro, with an I2C interface. The I2C interface is provided by

a PCF8547 I2C-to-parallel IC, which is inexpensive and

widely available. The Pro Micro code uses the standard Arduino

This article is about how to use the ubiquitous HD44780 LCD module

with a Arduino-like microcontroller board such as the SparkFun

Pro Micro, with an I2C interface. The I2C interface is provided by

a PCF8547 I2C-to-parallel IC, which is inexpensive and

widely available. The Pro Micro code uses the standard Arduino

Wire

library for I2C operation, and the Serial library

for USB communication. As a result, all the remaining

complexity in the

code is in interfacing with the I2C-to-parallel converter --

which is very fiddly indeed.

Note:I should point out from the start that Using an I2C interface is not an optimal way to interface the Arduino and the LCD, if you really do want to provide an auxiliary LCD display for a computer. That's because, if all the microcontroller does is operate the LCD module, it has enough GPIO pins to do it directly, using parallel data operations. Using an I2C interface significantly complicates the design and build, and generally slows down the communication.

I also have a article on interfacing the HD44780 to a Raspberry Pi using a similar method here.

However, the article is only partly about providing a USB interface to an LCD display -- it's also about how to use an I2C-to-parallel converter with an Arduino, to minimize the number of GPIO pins that are needed by the display. This is perhaps of more relevance if you're building something that actually uses an LCD display, but with other equipment connected, that also needs GPIO pins. Using potentially eight of the microcontroller's GPIO pins just to operate the LCD display is not very efficient. Using the I2C pins, we only need two data connections between the microcontroller and the display -- just the I2C SDA and SCL lines.

I have to point out also that I'm not going to describe any of the technical details of the HD44780 or the PCF8547 this article. I'll present the circuit diagram, of course, but the hardware is described in depth in my article on using the HD44780 with a Raspberry Pi. The sections of that article that deal with the HD44780 and the PCF8547 are as relevant to the Arduino as they are to the Raspberry Pi.

I will be showing only snippets of code from this application; the full source, and a pre-compiled binary, is available in my GitHub repository.

I wrote this article specifically for Linux users. The circuit and the

compiled Pro Micro firmware -- the .hex file in the

GitHub repository --

should work with other platforms, but I'm in no

position to say for sure, or to advise on how to use them.

In operation, the display looks something like this:

The basic idea

The HD44780 LCD display has been around for decades, and is found in all sorts of equipment. It can be purchased in single units for a few pounds. It has a rather old-fashioned parallel interface, using between six and twelve, 5V (nominal) logic lines. A minimum configuration uses four data lines (so two operations are needed to send one byte to the display), with the LED backlight permanently enabled, and the display permanently in "write" mode. The other two lines are the "register select" line, and the clock (also called "Enable" or "E" in some documentation). That gives the minimum number of connections -- six.

This minimal configuration is suitable for many applications. However, if you want to be able to control the backlight in software, then you'll need to connect something to its control pin. If you want to be able to read from the display (necessary if you're using custom graphics), then another pin will be connected to the R/W line on the display. And, of course, you could choose to use eight data lines rather than four, if you really needed the additional speed.

An Arduino-like microcontroller will typically have eighteen GPIO pins, so there's enough to use the HD44780 in its full-blown configuration, using dedicated pins. This is easy to program, as well as minimizing parts. However, using this many pins for the relatively slow operation of sending data to the LCD display seems rather wasteful. Using I2C needs only two controller pins but, of course, the HD44780 doesn't have any I2C support.

The PCF8574 is an I2C-to-parallel converter. It accepts 8-bit I2C data packets, and outputs them on eight data lines. It can also work as an input, reading eight data lines and providing them as a block to the I2C bus. The eight lines of the PCF8547 are enough to operate the HD44780 well in four-bit mode -- we use four outputs from the 8547 for the four data lines, and the other four for R/W , clock, register select, and the LED backlight.

This design is economical of GPIO pins, but very fiddly to program. That's because we can only change the state of a specific line on the HD44780 display by sending an entire 8-bit block over I2C. So the controller program has to keep track of which lines are set to which values at all times, so it can synthesize 8-bit blocks from the stored state of the display pins.

The complexities of the interface logic are described in much more detail in my my article on using the HD44780 with a Raspberry Pi, and are not significantly different when using an Arduino instead.

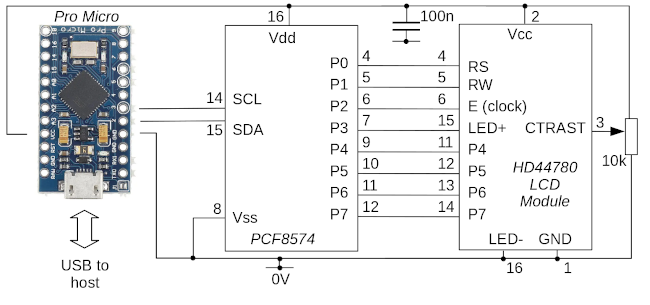

The circuit

Bearing in mind the factors described above, here is the complete circuit. Note that the decision about which output pins P0-P7 on the PCF8574 connect to which pins on the LCD module is completely arbitrary. P0-P7 are just general data outputs -- we'll need to take account in software of what is connected where. The pin assignments in the circuit match those in my Pro Micro code, but I've tried to make it clear in the source where you'd define different pin assignments.

Note:

There are a number of commercial HD44780 modules on the market, that include an I2C interface based on the PCF8574. These may, or many not, work with my controller code, depending on how the 8574 and the display are connected.

For future expansion, my design has the LCD display's R/W line connected to an output of the 8547, so the display can, in principle, be read. However, my code currently does not use this facility.

Arduino program

Because the USB logic is handled by libraries, the main body of the

program code is very simple. Here is a simplified version (the

full code is in usb_led.cpp).

LCD8574Arduino lcd (0x27, 16, 2);

void setup()

{

Serial.begin (57600);

lcd.init();

lcd.backlight_on();

}

void loop()

{

Serial.flush();

while (!Serial.available());

uint8_t c = Serial.read();

lcd.write_char (c);

}

All the logic for controlling the LCD panel via the PCF8547 IC

is in the class LCD8574Arduino (of which, more later).

The setup() function just initializes the lcd

instance and the Serial library.

The loop() method just waits for USB data to become

available, reads a character, and then passes it to the

write_char() method.

The implementation of the LCD8574Arduino class is

in lcd8574arduino.cpp. I think most of this class

is reasonable self-explanatory, if you have the HD44780 datasheet

to hand. The core of the class is the method send_byte(),

which does exactly what it says. Because we're using 4-bit mode,

this method splits the byte into two 4-bit chunks, and calls

write4bits on each. The write4bits

method calls write_i2c_byte() to set a byte

onto the I2C bus, and then calls do_clock() to

toggle the clock line for the necessary timing. Note that

each four-bit block of data requires a whole byte to be

written to the I2C bus. Of that byte, only four bits

are the data -- another bit is used for the "register select"

line, which will be 0 if we're sending a command, and 1 if

we're sending data. Another bit is used to control the LED

backlight; this value is stored as part of the program's

state, and merged into each I2C write.

The do_clock() method sets the clock (or Enable)

line high for one microsecond, and then low again for

50 microseconds. The time between clock strobes in the datasheet

is 37 microseconds, but I'm not sure how accurate the microsecond

timer on an Arduino board is. It seemed better to allow a bit

of a margin. Again, we can't just change the state of the

clock line, because we have to write all eight lines in

one operation over I2C; so the other (non-clock) lines are

written again, with their original values.

Most of the character values processed by write_char()

are simply passed to the LCD display as data bytes. However,

the code does recognize a few special characters.

Carriage return and line feed have their usual meanings, and

a form feed (character 12) clears the display completely.

This allows a client application to reset the display for

a new text update. There's no vertical scrolling built into

the code, but it would be relatively easy to add. However, this

would require adding logic to read characters from the LCD display,

or maintaining a buffer that holds a copy of the display contents.

In a more complex application, these additions might be useful.

In use

When running the application code, the Arduino acts like a

USB-to-serial converter. With a Linux host, it will usually

appear as a /dev/ttyUSB or /dev/ttyACM

device. Sending data to the appropriate device should cause

it to be displayed. On some Linux systems, the modem manager

will try to get control of the device when it detects it, which can lead to

conflicts. These are irritating, but don't usually cause

long-standing problems.

Closing remarks

Using an I2C-to-parallel adapter to connect an Arduino board to an LCD display is not fast, or easy to program. An alternative way to minimize the number of GPIO pins required, which is conceptually similar, would be to use a traditional logic-level shift register like the 74HC595 rather than an I2C-to-parallel device. This would be faster, and marginally cheaper, but would lose the ability to chain devices that I2C has.

Have you posted something in response to this page?

Feel free to send a webmention

to notify me, giving the URL of the blog or page that refers to

this one.